Talk with Our Production Team

Hello! We just need a few bits of information, and then a manufacturing expert will reach out to you directly to see how we can partner on a future production project.

Thank you! We've received your request and a member of our team will reach out shortly.

MADE IN CHINA SERVING THE WORLD

ANXIN, provides customized CNC machining parts with competitive price and quality, which also apply to many different industries. Our precise parts receive good response, with a wide client base spread throughout the European and American market. Please feel free to contact us for offering more customized services.

ISO 9001:2015 certified

Diversified Processing Services from Prototyping to Production

From prototype to mass production, Anxin always provides customers high quality products and fast delivery processing services.

Requirement Analysis & Quotationget in touch with us and send us your products’ drawings for reviewing. |

Order Confirmation & ContractCustomer approves the quote and signs a service agreement. |

Production & Quality ControlRaw material procurement and inspection. |

Final Inspection & ApprovalFull dimensional inspection and performance testing (e.g., CMM, hardness tests). Share inspection reports (PDF/QC sheets) for customer approval. |

Packaging & ShippingProtective packaging (anti-rust, shockproof) per customer requirements. |

After-Sales ServicesWarranty coverage for defects (terms outlined in the contract). |

Our Manufacturing Services

CNC MachiningAnxin offers services for both metal and non-metal parts from prototypes to on-demand production. You can receive immediate quotations and choose from over 40 materials and more than 10 surface treatments. |

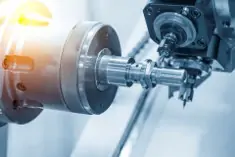

CNC TurningIt is usually suitable for precision machining of a variety of materials and complex parts. It has the advantage of composite processing and simplifies subsequent processes. |

5 Axis CNC MachiningANXIN’s 5-axis machining services offer unparallel speed and flexibility. With an extensive range of advanced 5-axis CNC machines and a long list of materials. |

Sheet Metal FabricationWe transform flat sheets of metal into precise, functional components and enclosures through cutting, bending and assembly. |

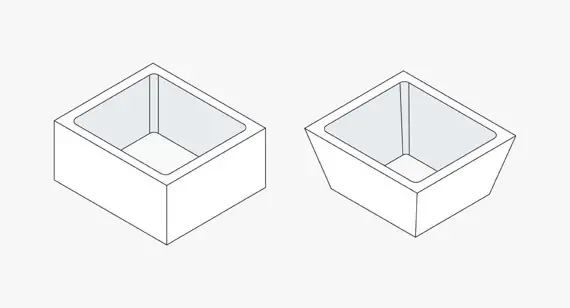

Die CastingDie casting is an efficient metal casting process in which molten metals (such as aluminum, zinc, magnesium alloy) are injected into precision steel molds at high speed and cooled in a short time. |

Injection MoldingInjection molding is a kind of molding process in which molten plastic is injected into a closed mold cavity by high pressure, and plastic products are obtained after cooling and curing. |

3D PrintingBring Your Ideas to Life.We transform digital designs into physical objects, layer by layer. Perfect for prototyping, custom parts, or creative projects. |

Wire EDMWe specialize in machining ultra-hard metals and complex shapes using controlled electrical sparks. The ideal solution when traditional CNC cutting is impossible or inefficient. |

What Our Clients Say About Us

Clinton Say:Anxin provides competitive pricing and fast lead times. I received my parts in a few weeks and they met all the specifications I had laid out. I would recommend you as a quality supplier. |

Joe Say:You will be on my list of companies that do excellent work, on time, with great communication. I’m very happy with the work Anxin Metal has done for me in the past. |

Jordan Say:Parts came out excellent, good communication, and their machinists has good intuition. Will do business again. |

Equipment for CNC Machining Factory

CNC machining factoryEstablished :2011 |

Metal fabrication factoryEstablished :2015 |

Injection mold factoryEstablished :2015 |

Die casting factoryEstablished :2019 |

3D printing factoryEstablished :2019 |

EDM factoryEstablished :2021 |

How to Work With Us

Upload a CAD File

Start by choosing your preferred manufacturing process, then upload your design file.

Get a Quote

Next, configure project details like material, finishing option, and quantity, receive an accurate quote and DFM feedback, then place your order.

Parts Delivered!

Once production is complete and your parts pass quality inspections, they are shipped to you.

End-to End Solutions for New Product Development

Design & Engineering

expand_less

expand_more

Design & Engineering

expand_less

expand_more

Design & Engineering

The core phase of transforming ideas into feasible solutions. Through engineering simulation and optimization, it ensures the optimal balance between aesthetics, functionality, and manufacturability.

Industrial Design

Develop conceptual sketches and product renders to finalize the engineering definition of product appearance.

Mechanical Design

Deliver detailed engineering drawings and documentation compliant with Design for Manufacturability (DFM) requirements.

CMF Design

Plan color, material, and finish specifications to achieve a balance between aesthetic appeal and durability.

Cost Estimation

Provide early-stage cost projections based on the design, along with customized cost-optimization strategies for the target market.

Rapid Prototyping

expand_less

expand_more

Rapid Prototyping

expand_less

expand_more

Rapid Prototyping

The process of quickly turning digital models into physical prototypes. It is used for functional testing, user experience validation, and design iteration, significantly shortening development cycles and reducing early-stage risks.

Manufacturing Advisory Services

Material selection, Design for Manufacturability (DFM) analysis, and recommendations for structural and process optimization.

Assembly and Testing Support

Guidance on assembly processes, development of testing protocols, and delivery of key phase verification reports.

Low-Volume Pilot Production

Execution of small-batch production verification, implementation of full inspection, and enforcement of quality control plans.

Mass Production

expand_less

expand_more

Mass Production

expand_less

expand_more

Mass Production

After product validation, the transition into efficient, standardized, and cost-optimized large-scale manufacturing. Leveraging mature supply chains and quality management systems ensures consistent and reliable product delivery.

Supply Chain Integration

Conduct supplier evaluations and deliver systematic audit reports with integration recommendations.

Raw Material Procurement & Management

Assist in developing procurement strategies and perform quality inspection and supply management of raw materials.

Production Time Management

Assist in controlling project timelines, offering actionable estimates aligned with project objectives.

Mass Production Technical Support

Provide process optimization and quality control solutions to ensure smooth production scale-up.

Packaging Phase

expand_less

expand_more

Packaging Phase

expand_less

expand_more

Packaging Phase

Going beyond mere protection, packaging is an extension of brand experience and a direct expression of product value. It integrates brand identity, user experience, logistics compatibility, and sustainability considerations.

Packaging Design

Deliver graphic and structural design solutions, including both 2D and 3D drawings.

Packaging Supplier Management

Conduct qualification reviews of packaging suppliers and provide evaluation analysis reports.

Packaging Sample Testing

Execute sample inspections and deliver sample test reports.

Packaging Execution

Provide packaging production plans, bill of materials, and final production summary reports.

Delivery Services

expand_less

expand_more

Delivery Services

expand_less

expand_more

Delivery Services

The final critical step from production line to end-user. Through flexible and reliable logistics and distribution solutions, it ensures safe, timely, and fully traceable delivery, completing the user experience cycle.

Order Processing & Fulfillment

Handling customer orders, managing inventory, and arranging picking and packing, initiating the delivery process.

Warehousing & Inventory Management

Providing secure and efficient storage solutions with real-time inventory monitoring and optimization to ensure product availability.

Transportation Modes & Planning

Planning and managing cross-border trunk line transportation solutions such as air, sea, or international land freight based on cost and time requirements.

After-Sales Service Delivery

Ensuring value-added services such as installation, debugging, and training accompanying the product are delivered accurately and promptly to customers.

FAQs

Why Choose to cooperate with Anxin?

expand_less expand_moreOne-stop services

One-stop services manufacturer for products desgin, machining, assembly and reliable testing.

High Quality

Anxin has four-axis, five-axis and other precision machining equipments. The stable processing quality and high precision products have helped us win the praise of many customers.

Professional Team

Our team puts the needs of our customers first and provides timely & professional solutions.

Is there any quality assurance?

expand_less expand_moreOur QC inspection for each process, from raw materials to finish products would be proceeded accordingly;

Quality Control Process in Each order:

1.In coming Quality Control (IQC)

2.In Production Inspection Control (IPQC/PQC)

3.Final Quality Control (FQC)

How you know the order status without visiting our company?

expand_less expand_moreA detailed production schedule and weekly reports with digital pictures and videos during the process could be provided if you need.

We have our own factory, with experienced engineer and production team. It's convenient to provide the real-time production and relant updated information.

Which payment term you could choose?

expand_less expand_more40% prepay then the balance paid before final delivery via Paypal/VEEM/Bank Transfer.

Net 30 days or other payment terms need to be confirmed after your inquiry and further communication.

How to get the quote?

expand_less expand_morePlease send your PDF or 3D drawings(.STP, .IGS, .STEP format) to us, and indicate the material, surface treatment and quantities, then the quote would be provided in 12 hours after confirmation.

If you have any other specific requirements, just let us know when you inquiring.

What’s New at Anxin Metal?

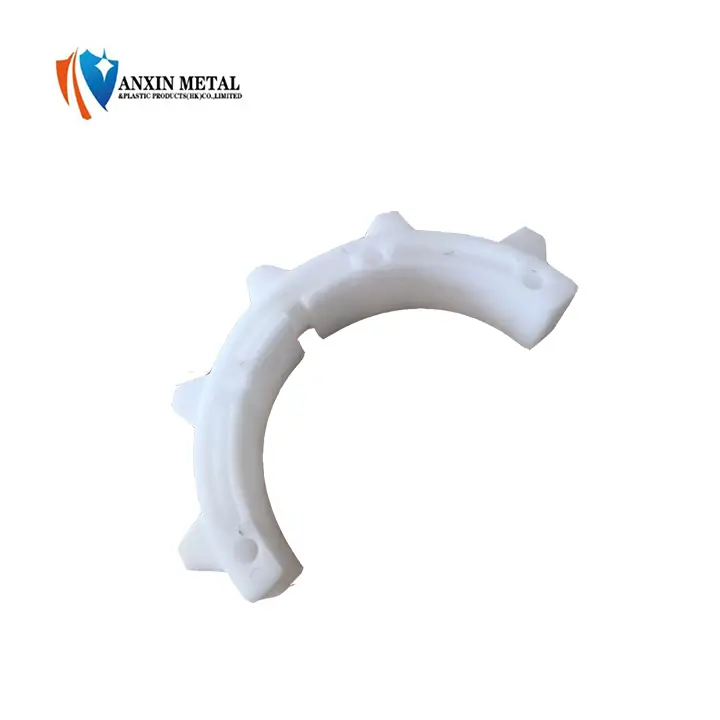

High Demand Injection molding Plastic ComponentsMaterial: White Nylon6/6 |

OEM 5 Axis Machining Items with Competitive PriceMaterial: AL 6061-T6 |

High Quality & Cheap Price CNC Milling ComponentMaterial: AL6061-T6 |