Latest Posts

What processes can be used to milling machining to improve product quality?2026-02-16 Milling machining is a commonly used metal machining method, which achieves the purpose of machining by rotating the tool to cut the metal workpiece. |

How does the machining process improve the competitiveness of the product?2026-02-16 Machining process is one of the key links of manufacturing industry, which has an important impact on product quality, cost and delivery cycle. |

What impact does the development of machining technology have on the economy?2026-02-16 With the continuous development of science and technology, machining technology plays a vital role in the manufacturing industry. |

How does machining production meet the needs of different customers?2026-02-16 Machining production, as an important production mode, has its unique advantages and characteristics in meeting different customer needs. |

Comparison of advantages and disadvantages of CNC machining center and CNC milling machine2026-02-16 CNC machining centers and CNC milling machines are common CNC machine tools, which play a very important role in industrial production. |

How to check the machining accuracy of CNC machining center?2026-02-16 CNC machining centers are one of the commonly used processing equipment in modern manufacturing industry, with the advantages of high precision, high efficiency, and high stability. |

What Are Advantages Of CNC Machining?2026-02-11 One of the most significant advantages of CNC machining in our factory compared to manual machining is precision. |

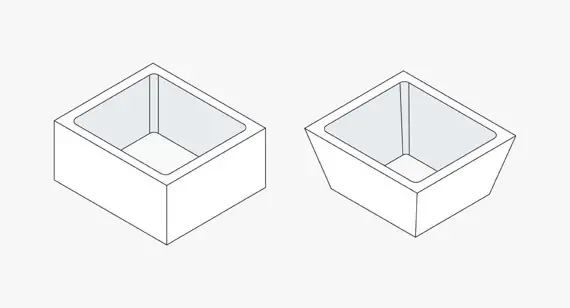

OEM / ODM Casting Services - Anxin CNC2026-02-11 Casting-After the metal is melted into a liquid state, it is poured into the cavity of the model that is suitable for the shape and size of the part to be formed. After the liquid metal is cooled and solidified, the mold is opened (or destroyed) to take out the formed casting blank. |

OEM/ ODM CNC Machining Parts Services2026-02-11 CNC machining is a mechanical machining method that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of variable parts variety, small batch, complex shape and high precision, and to realize high efficiency and automatic processing. |