What is Laser Cutting?

2026-02-20

Laser cutting uses a beam of light to cut or engrave materials without making physical contact. The laser beam melts or vaporizes the material along a pre-programmed path. Laser cutters are particularly effective for cutting and engraving thin materials like plastic, wood, and acrylic.

Key Components of Laser Cutting:

- Laser Beam: A focused beam of light that melts, burns, or vaporizes the material.

- Assist Gas: Helps clear debris and cools the cutting surface.

- Focal Point: Determines the precision and cutting depth.

Laser cutting machines are faster and more precise than CNC in many cases, especially when working with thin materials. The wide range of materials that can be cut, along with its speed and precision, make laser cutting an appealing option for signage and artwork.

What are the Key Differences between CNC vs Laser Cutter

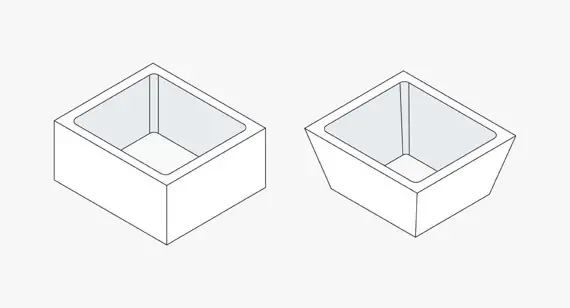

The primary difference between CNC and laser cutters is their cutting mechanism. CNC machines physically remove material using spinning bits, whereas laser cutters rely on a laser beam to melt or vaporize material. Here’s a quick comparison:

| Feature | CNC Cutter | Laser Cutter |

|---|---|---|

| Material Thickness | Works well with thick materials | Best for thin materials |

| Precision | ±0.01mm or better | ±0.05mm or better |

| Speed | Slower for thicker cuts | Faster, especially for thinner materials |

| Complexity | Ideal for 3D designs and intricate cuts | Great for detailed engraving |

| Tooling | Spinning bits wear over time | Laser beam doesn’t wear |

Laser cutters are highly effective for detailed cuts on thin materials and high-speed operations, while CNC cutters offer versatility and precision, especially when working with thicker materials.

Which Materials are Best for CNC Cutting?

Laser cutters are highly effective for detailed cuts on thin materials and high-speed operations, while CNC cutters offer versatility and precision, especially when working with thicker materials. Understanding the laser cutter vs CNC comparison and the specific advantages of CNC router vs laser cutter helps you select the right equipment for your workshop and project requirements.

Materials CNC Works Well With:

- Metals: Aluminum, Steel, Titanium

- Wood: Hardwood, Plywood, MDF

- Plastics: Acrylic, Nylon, PVC

- Composites: Carbon Fiber, Fiberglass

For woodworking, CNC routers are ideal because they can handle thicker pieces of wood and create detailed joinery or milling operations. CNC machines offer more control over depth of cut than laser cutters.

Which Materials are Best for Laser Cutting?

Laser cutters perform best with thin materials such as wood, acrylic, and plastics. They offer precision cutting, making them the go-to for applications like engraving, signage, and decorative pieces.

Materials Laser Cutting Works Well With:

- Wood: Thin hardwoods, Plywood

- Acrylic: Clear and colored

- Plastics: PETG, Polycarbonate

- Rubber: For seals, gaskets

Laser cutting is not ideal for thicker materials, but it excels at producing detailed cuts on materials like wood and plastic.

Which is More Precise: CNC or Laser Cutting?

Laser cutters generally provide higher precision than CNC, especially for intricate designs and fine detail work. A laser beam can achieve precision levels as fine as 0.05mm, while CNC machines can reach ±0.01mm. However, CNC machines offer greater control over depth of cut, making them better for thicker or multi-dimensional cuts.

For engraving, laser machines are particularly effective. For 3D milling or cutting thicker materials, CNC machines are the preferred option.

Which is Faster: CNC or Laser Cutting?

Laser cutting is typically faster than CNC, especially for thin materials. Laser cutting can make precise cuts at speeds of up to 120 inches per minute, while CNC cutting is generally slower, particularly when working with thicker materials. However, CNC systems can outperform lasers when depth of cut or 3D cutting is required.

Costs of CNC and Laser Cutting

The initial cost for a CNC machine is generally higher due to the need for mechanical parts, spindles, and tools. Laser cutters have lower maintenance costs because there are fewer moving parts, but they may be costlier for industrial use depending on the laser type (CO2 vs. fiber).

Laser cutting machines often come with lower operating costs for thin materials but require regular lens replacement. In contrast, CNC machines require bit replacements and tool maintenance more frequently.

Maintenance Requirements for CNC vs Laser Cutters

CNC machines require regular tool changes, machine calibration, and cleaning of debris and dust. Laser cutters need less mechanical maintenance, but optics and gas systems require regular checks to maintain cutting precision. Both types of equipment need environmental management: CNC systems require dust collection, while laser systems need fume extraction.

Safety Considerations for CNC and Laser Cutters

CNC machines involve moving parts, spinning bits, and sharp edges, so it’s essential to wear PPE like goggles and ear protection. Laser cutters, on the other hand, involve high-intensity light, and thus require laser safety glasses and enclosures to prevent exposure to the laser beam.

Proper ventilation and fume management are essential for both types of machines to ensure the safety of the work environment.

CNC Machine vs Laser Cutting: Which One Should You Choose?

Choosing between CNC cutting and laser cutting comes down to project specifics. If your project involves thick materials, intricate 3D designs, or precision milling, then CNC routing or CNC milling is the best choice. For detailed cuts, engraving, and high-speed operations on thin materials, laser cutting is ideal.

CNC cutting provides greater versatility for different material types and thicknesses, while laser cutting offers speed and precision for fine details.

Unsure which cutting method is right for your project? Contact us today for a detailed consultation to determine whether CNC or laser cutting is best for your needs, and explore how Anxin can help bring your designs to life!