Total Manufacturing Expertise

Our Manufacturing Services

Anxin offers one-stop manufacturing services, covering precision CNC machining, sheet metal fabrication, 3D printing, and a full range of capabilities. From complex precision components to large structural parts, we deliver efficiently to meet your diverse manufacturing needs.

CNC Machining

Anxin offers services for both metal and non-metal parts from prototypes to on-demand production. You can receive immediate quotations and choose from over 40 materials and more than 10 surface treatments.

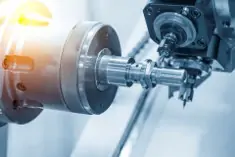

CNC Turning

It is usually suitable for precision machining of a variety of materials and complex parts. It has the advantage of composite processing and simplifies subsequent processes.

5 Axis CNC Machining

ANXIN’s 5-axis machining services offer unparallel speed and flexibility. With an extensive range of advanced 5-axis CNC machines and a long list of materials.

Sheet Metal Fabrication

We transform flat sheets of metal into precise, functional components and enclosures through cutting, bending and assembly.

Die Casting

Die casting is an efficient metal casting process in which molten metals (such as aluminum, zinc, magnesium alloy) are injected into precision steel molds at high speed and cooled in a short time.

Injection Molding

Injection molding is a kind of molding process in which molten plastic is injected into a closed mold cavity by high pressure, and plastic products are obtained after cooling and curing.

3D Printing

Bring Your Ideas to Life.We transform digital designs into physical objects, layer by layer. Perfect for prototyping, custom parts, or creative projects.

Wire EDM

We specialize in machining ultra-hard metals and complex shapes using controlled electrical sparks. The ideal solution when traditional CNC cutting is impossible or inefficient.

Why Choose to cooperate with Anxin?

✩One-stop services One-stop services manufacturer for products desgin, machining, assembly and reliable testing.

✩High Quality Anxin has four-axis, five-axis and other precision machining equipments. The stable processing quality and high precision products have helped us win the praise of many customers.

✩Professional Team Our team puts the needs of our customers first and provides timely & professional solutions.

Consulting & Engineering Capabilities

Materials & Surface Finishes

Materials

We provide an extensive range of materials — from durable metals and versatile plastics to high-strength composites — to support your diverse project requirements.

View all Materials

Surface Finishes

Our superior surface finishing solutions enhance both the longevity and aesthetic quality of your components, perfectly addressing the needs of applications requiring smooth or custom-textured surfaces.

FAQs for CNC Machining

What’s the key difference between CNC machining and 3D printing for precision parts?

expand_less expand_moreA: CNC is subtractive (cuts material to shape) for tight tolerance & high strength; 3D printing is additive (builds layer by layer) for complex geometries & low-volume prototypes fast.

How to choose between mold injection molding and 3D printing for mass production?

expand_less expand_moreA: Injection molding is ideal for high-volume runs (cost-effective per unit); 3D printing fits small batches, custom parts or urgent prototypes without mold costs.

What materials are most suitable for high-precision CNC machining of industrial components?

expand_less expand_moreA: Aluminum alloys, stainless steel, titanium alloy, brass and engineering plastics like POM are top choices for high precision and industrial durability.

Can 3D printed parts be directly used as molds for small-batch injection molding?

expand_less expand_moreA: Yes, rigid materials like resin or metal 3D prints work for low-temperature plastics small-batch runs, but not for high-volume or high-heat injection molding.

What factors affect the surface finish and dimensional accuracy of injection molded products?

expand_less expand_moreA: Mold precision, material shrinkage rate, injection pressure, cooling speed and gate design are the core influencing factors.

How to reduce the lead time for CNC machining or mold making for urgent orders?

expand_less expand_moreA: Prioritize simplified designs, use pre-stocked materials, adopt fast prototyping and confirm specs upfront to avoid reworks.