Machine Tool Industry

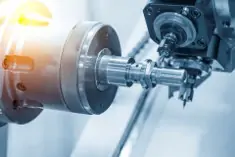

Anxin specializes in the precision

machining and custom assembly of core machine tool components. We fabricate

high-hardness parts including spindle brackets, slide rail fixtures, and gear

housings, engineered to meet the stringent precision and durability demands of

industrial machine tools. Our strict quality inspection procedures ensure

consistent performance, supporting machine tool manufacturers in optimizing

equipment stability and operational efficiency.

Customized Solutions for the Machine Tool Industry

1. Core Part Precision Machining

High-precision CNC machining for machine tool core components (spindles, slide rails, tool holders, base parts) with strict tolerance control, ensuring the machining accuracy and operational stability of machine tool equipment.

2. Heavy-Duty & High-Rigidity Machining Customization

Tailored machining processes for large, heavy-duty machine tool structural parts, optimizing milling, turning and boring processes to enhance component rigidity and load-bearing capacity, matching the high-performance operation requirements of machine tools.

3. Material & Surface Treatment Matching

Professional machining for machine tool-specified materials (alloy steel, cast iron, hard alloy) and customized surface finishing (quenching, tempering, grinding, plating), improving component wear resistance, corrosion resistance and service life.

4. Non-Standard Component Customization

One-stop customized machining for non-standard machine tool accessories and functional parts, flexibly meeting the personalized design and upgrading transformation needs of different machine tool models.

5. High-Efficiency Machining & Assembly Adaptation

Optimize component dimensional consistency and structural design combined with machine tool assembly processes, achieving seamless fit of parts, reducing assembly debugging time and improving the overall production efficiency of machine tool equipment.

Why Choose Us?

Anxin is a dependable machining partner for the machine tool industry, with high-precision & high-rigidity machining, professional hard material processing, strict quality control and customized non-standard part solutions, delivering stable and durable machining support for machine tool core components

*High-Precision & High-Rigidity Machining

Strict tolerance control, optimized machining processes for structural parts, ensuring machine tool operational accuracy and stability.

*Professional Hard Material Processing

Mature technology for alloy steel, hard alloy and other machine tool-specified materials, with matching heat treatment for wear resistance.

*Rigorous Multi-Stage Quality Control

High-precision testing for dimensional accuracy and rigidity, ensuring part consistency and long-term service life of machine tools.

*Customized Non-Standard Part Machining

One-stop customization for non-standard machine tool fixtures and core parts, flexible adaptation to personalized design needs.

Our Manufacturing Services

Anxin offers one-stop manufacturing services, covering precision CNC machining, sheet metal fabrication, 3D printing, and a full range of capabilities. From complex precision components to large structural parts, we deliver efficiently to meet your diverse manufacturing needs.

CNC Machining

Anxin offers services for both metal and non-metal parts from prototypes to on-demand production. You can receive immediate quotations and choose from over 40 materials and more than 10 surface treatments.

CNC Turning

It is usually suitable for precision machining of a variety of materials and complex parts. It has the advantage of composite processing and simplifies subsequent processes.

5 Axis CNC Machining

ANXIN’s 5-axis machining services offer unparallel speed and flexibility. With an extensive range of advanced 5-axis CNC machines and a long list of materials.

Sheet Metal Fabrication

We transform flat sheets of metal into precise, functional components and enclosures through cutting, bending and assembly.

Die Casting

Die casting is an efficient metal casting process in which molten metals (such as aluminum, zinc, magnesium alloy) are injected into precision steel molds at high speed and cooled in a short time.

Injection Molding

Injection molding is a kind of molding process in which molten plastic is injected into a closed mold cavity by high pressure, and plastic products are obtained after cooling and curing.

3D Printing

Bring Your Ideas to Life.We transform digital designs into physical objects, layer by layer. Perfect for prototyping, custom parts, or creative projects.

Wire EDM

We specialize in machining ultra-hard metals and complex shapes using controlled electrical sparks. The ideal solution when traditional CNC cutting is impossible or inefficient.

Machine Tool Industry

Materials & Surface Finishes

Materials

We provide an extensive range of materials — from durable metals and versatile plastics to high-strength composites — to support your diverse project requirements.

View all Materials

Surface Finishes

Our superior surface finishing solutions enhance both the longevity and aesthetic quality of your components, perfectly addressing the needs of applications requiring smooth or custom-textured surfaces.

View all Surface Finishes

Applications of Machine Tool Parts

Our high-precision, high-rigidity

machined components deliver exceptional durability and stability, engineered to

meet the heavy-duty, high-precision demands of industrial machine tools and

equipment.

- Machine Tool Structures: Base frame fittings, slide rail

components and spindle brackets, ensuring machining accuracy and structural

rigidity for CNC lathes and milling machines.

- Transmission Systems: Gear shaft parts, bearing housings and

coupling components, optimizing rotational precision and load capacity for

smooth power transmission.

- Tooling & Fixturing: Precision clamps, tool holders and

fixture bases, matching the high-precision positioning requirements of

machining operations.

- Control & Actuation: Linear guide parts, actuator brackets

and sensor mounts, guaranteeing responsive and accurate motion control for

automated machine tools.