Medical Industry

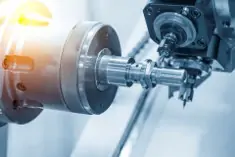

Anxin specializes in the precision

machining and assembly of high-quality medical device components. We produce

custom parts such as surgical instrument fittings, diagnostic equipment frames

and lightweight alloy brackets, all manufactured to meet strict medical

industry standards for sterility and durability. Our rigorous quality control

processes ensure every component delivers reliable performance, catering to the

exacting needs of medical equipment manufacturers worldwide.

Customized Solutions for the Medical Industry

1. Medical Device Precision Machining

High-precision CNC machining for core medical device components (surgical instruments, diagnostic equipment parts, implant accessories, medical pump components) with ultra-tight tolerance control, meeting the high-precision and stability requirements of medical equipment operation.

2. Biocompatible Material Machining

Professional tailored processing for medical-specified biocompatible materials (titanium alloy, medical stainless steel, PEEK, medical grade plastics), complying with medical material safety standards and ensuring material performance matches clinical application needs.

3. Compliance & Precision Surface Customization

Customized medical-grade surface finishing (electropolishing, passivation, precision grinding, sandblasting) to achieve smooth, corrosion-resistant, bacteria-resistant surfaces, meeting the sterility and biocompatibility requirements of medical device use.

4. Prototype to Batch Production Integration

One-stop machining support from rapid prototype development for medical device R&D verification to small/batch production, adapting to the industry’s strict product testing cycle and flexible production demands for customized medical equipment.

5. Full-Traceability Quality Control

Full-process quality management in line with medical industry standards (ISO 13485), with professional precision testing and complete production data traceability, guaranteeing the safety, reliability and consistency of machined medical components.

Why Choose Us?

Anxin is a reliable machining partner for the medical industry, with medical-grade precision machining, biocompatible material processing, strict quality control and customized small-batch production, providing safe and reliable machining solutions for medical device components.

Medical-Grade Precision Machining

Micron-level tolerance control for surgical instruments and diagnostic equipment parts, meeting the high-precision and stable operation demands of medical devices.

Biocompatible Material Processing

Professional machining for

titanium alloy, medical stainless steel and PEEK, complying with medical

material safety standards.

Rigorous Multi-Stage Quality Control

Full-process precision inspection, ensuring sterility, consistency and reliability of medical machined parts.

Flexible Customized Production

Support rapid prototype R&D and small-batch customization, adapting to the personalized R&D and production needs of medical devices.

Our Manufacturing Services

Anxin offers one-stop manufacturing services, covering precision CNC machining, sheet metal fabrication, 3D printing, and a full range of capabilities. From complex precision components to large structural parts, we deliver efficiently to meet your diverse manufacturing needs.

CNC Machining

Anxin offers services for both metal and non-metal parts from prototypes to on-demand production. You can receive immediate quotations and choose from over 40 materials and more than 10 surface treatments.

CNC Turning

It is usually suitable for precision machining of a variety of materials and complex parts. It has the advantage of composite processing and simplifies subsequent processes.

5 Axis CNC Machining

ANXIN’s 5-axis machining services offer unparallel speed and flexibility. With an extensive range of advanced 5-axis CNC machines and a long list of materials.

Sheet Metal Fabrication

We transform flat sheets of metal into precise, functional components and enclosures through cutting, bending and assembly.

Die Casting

Die casting is an efficient metal casting process in which molten metals (such as aluminum, zinc, magnesium alloy) are injected into precision steel molds at high speed and cooled in a short time.

Injection Molding

Injection molding is a kind of molding process in which molten plastic is injected into a closed mold cavity by high pressure, and plastic products are obtained after cooling and curing.

3D Printing

Bring Your Ideas to Life.We transform digital designs into physical objects, layer by layer. Perfect for prototyping, custom parts, or creative projects.

Wire EDM

We specialize in machining ultra-hard metals and complex shapes using controlled electrical sparks. The ideal solution when traditional CNC cutting is impossible or inefficient.

Medical Industry

Materials & Surface Finishes

Materials

We provide an extensive range of materials — from durable metals and versatile plastics to high-strength composites — to support your diverse project requirements.

View all Materials

Surface Finishes

Our superior surface finishing solutions enhance both the longevity and aesthetic quality of your components, perfectly addressing the needs of applications requiring smooth or custom-textured surfaces.

View all Surface Finishes

Applications of Medical Parts

Our precision-machined medical

components feature exceptional accuracy and material compatibility, engineered

to meet the strict safety, precision and reliability demands of medical devices

and clinical equipment.

- Surgical Instruments: Precision cutting, grasping and

retracting tool components, ensuring sharpness, structural stability and

sterilization compatibility for surgical procedures.

- Diagnostic Equipment: Sensor mounts, probe fittings and

instrument housings, guaranteeing precise positioning and stable performance

for imaging and testing devices.

- Patient Care Devices: Component parts for monitoring

equipment, infusion pumps and rehabilitation devices, complying with

biocompatibility and operational safety standards.

- Dental Equipment: Precision dental handpiece parts,

implant fixtures and instrument components, meeting the micro-precision and

wear-resistance requirements of dental care.