Photography Industry

Anxin

specializes in precision machining and assembly of custom camera accessories

and photography equipment components. Our offerings cover camera mounts,

stabilizer frames, and lightweight alloy brackets, all crafted to meet the

strict durability and precision demands of professional photography scenarios.

Backed by advanced CNC technology and rigorous quality checks, we deliver

tailored solutions that elevate the stability and performance of photography

gear for both commercial studios and individual creators.

Customized Solutions for the Photography Industry

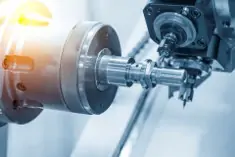

1. Precision Structural Component Machining

High-precision CNC machining for core photography equipment parts (camera bodies, lens barrels, tripod joints, filter frames) with micron-level tolerance control, matching the miniaturization and high-precision assembly demands of photographic gear.

2. Lightweight & High-Strength Material Machining

Tailored processing for photography-specified materials (aluminum alloy, magnesium alloy, carbon fiber composites, engineering plastics), optimizing material cutting and forming processes to balance product lightweight design and structural strength.

3. Surface Finishing & Aesthetic Customization

Customized surface treatments (anodizing, sandblasting, precision polishing, laser engraving) for photographic components, meeting anti-scratch, anti-reflection, aesthetic and brand marking requirements of photography equipment.

4. Prototype & Small-Batch Custom Machining

One-stop support from rapid prototype machining for new photography product R&D to small-batch customized production, adapting to the industry’s personalized design, limited-edition product development and fast iteration needs.

5. Assembly-Friendly Part Machining

Optimize component dimensional accuracy and structural fit based on photography equipment assembly requirements, ensuring seamless matching of precision parts (e.g., lens focusing structures, shutter components) and reducing assembly debugging costs.

Why Choose Us?

Anxin is a reliable machining partner for the photography industry, with micron-level precision machining, lightweight high-strength material processing, customized surface finishing and flexible small-batch production, providing high-quality machining solutions for photography equipment components.

*Ultra-Precision Machining

Micron-level tolerance control for lens barrels, gimbal brackets and core parts, meeting the high-precision assembly demands of photography equipment.

*Lightweight & High-Strength Machining

Tailored processing for aluminum/magnesium alloy and engineering plastics, balancing equipment lightweight design and structural strength.

*Customized Surface Finishing

Anodizing, sandblasting and precision polishing, meeting anti-scratch, anti-reflection and aesthetic requirements of photography parts.

*Flexible Small-Batch Customization

Support rapid prototype R&D and small-batch production, adapting to the personalized design and fast iteration of photography equipment.

Our Manufacturing Services

Anxin offers one-stop manufacturing services, covering precision CNC machining, sheet metal fabrication, 3D printing, and a full range of capabilities. From complex precision components to large structural parts, we deliver efficiently to meet your diverse manufacturing needs.

CNC Machining

Anxin offers services for both metal and non-metal parts from prototypes to on-demand production. You can receive immediate quotations and choose from over 40 materials and more than 10 surface treatments.

CNC Turning

It is usually suitable for precision machining of a variety of materials and complex parts. It has the advantage of composite processing and simplifies subsequent processes.

5 Axis CNC Machining

ANXIN’s 5-axis machining services offer unparallel speed and flexibility. With an extensive range of advanced 5-axis CNC machines and a long list of materials.

Sheet Metal Fabrication

We transform flat sheets of metal into precise, functional components and enclosures through cutting, bending and assembly.

Die Casting

Die casting is an efficient metal casting process in which molten metals (such as aluminum, zinc, magnesium alloy) are injected into precision steel molds at high speed and cooled in a short time.

Injection Molding

Injection molding is a kind of molding process in which molten plastic is injected into a closed mold cavity by high pressure, and plastic products are obtained after cooling and curing.

3D Printing

Bring Your Ideas to Life.We transform digital designs into physical objects, layer by layer. Perfect for prototyping, custom parts, or creative projects.

Wire EDM

We specialize in machining ultra-hard metals and complex shapes using controlled electrical sparks. The ideal solution when traditional CNC cutting is impossible or inefficient.

Photography Industry

Materials & Surface Finishes

Materials

We provide an extensive range of materials — from durable metals and versatile plastics to high-strength composites — to support your diverse project requirements.

View all Materials

Surface Finishes

Our superior surface finishing solutions enhance both the longevity and aesthetic quality of your components, perfectly addressing the needs of applications requiring smooth or custom-textured surfaces.

Applications of Photography Parts

Our precision-machined photography

components deliver ultra-fine dimensional accuracy and structural stability,

engineered to meet the high-precision and aesthetic demands of professional

photography and imaging equipment.

- Camera Bodies & Lenses: Precision lens barrels, focus rings and

structural fittings, ensuring smooth mechanical movement and optical alignment

for professional cameras and lenses.

- Gimbals & Stabilizers: Gimbal brackets, pivot shafts and

damping components, guaranteeing stable, shake-free motion for camera

stabilizers and aerial photography gimbals.

- Tripods & Supports: Precision connecting parts, locking

components and mount adapters, balancing structural strength and lightweight

design for tripods and camera rigs.

- Accessories & Attachments: Filter holders, lens hood fittings and

flash mounts, meeting the precise assembly and aesthetic requirements of

photography accessories.